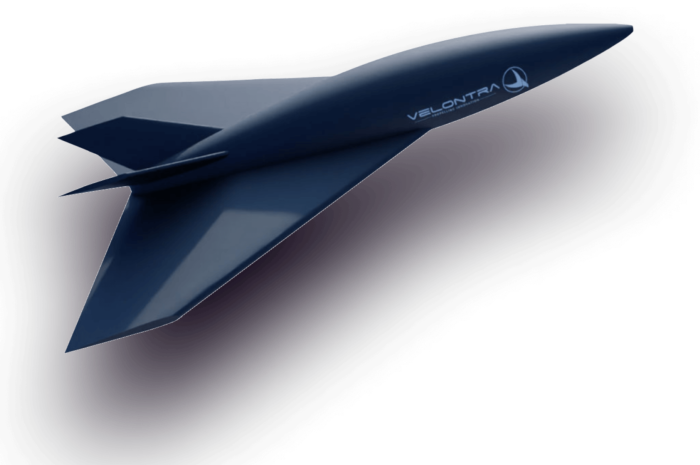

Take Your Career to New Heights

At Velontra, we are looking for exceptional individuals to join us in transforming air-breathing propulsion. We seek candidates with a passion for aerospace and the ability to thrive in a startup environment, where initiative and flexibility are required in the face of evolving tasking, product requirements, and internal processes. We offer work-life balance, respecting the boundary between the personal and professional, and allowing team members to succeed by focusing only on facts and technical challenges at work.

Limitless Innovation

Collaborative Culture

Exciting Challenges

Talented People We Seek

Visionaries

We seek individuals who dream big, possess a forward-thinking mindset, and embrace disruptive ideas. If you're someone who thrives on envisioning a better tomorrow and transforming ideas into reality, you'll find a perfect home at Velontra.

Technological Wizards

Whether you're a coding maestro, a data scientist extraordinaire, or a UX/UI virtuoso, we're searching for top-notch tech talent. Join us if you want to work with cutting-edge technologies and build remarkable products that leave a lasting impression.

Collaborative Champions

We value teamwork and the ability to work seamlessly with colleagues from diverse backgrounds. If you excel at communication, have a knack for building strong relationships, and enjoy collaborative problem-solving, we'd love to have you on board.

If this sounds like you and your interested in one of the roles below, please send you resume and cover letter to:

CURRENT OPENINGS:

Principal Turbomachinery Engineer

ExpandJob Title: Principal Turbomachinery Engineer

Description:

Velontra is seeking a principal turbomachinery engineer. This engineer will design, source, and test all types of turbomachinery hardware. This includes compressors, turbines, pumps, rotating assemblies, support structure, secondary flow systems, bearings, and seals.

Responsibilities:

The turbomachinery engineer is responsible for the following:

- Owning various turbomachinery hardware designs over the full product life cycle

- Performing system-level sizing of turbomachinery to fulfill vehicle requirements

- Performing detailed design and analysis of turbomachinery components based on system-level sizing and other requirements

- Developing static, dynamic, and/or thermal loads for use in design, based on test data and/or theory

- Managing hardware versions and configurations in product lifecycle management (PLM) and computer-aided design (CAD) software

- Specifying test approaches, including selecting instrumentation and providing test requirements, to validate designs

- Interpreting test data to compare as-tested performance to design intent

- Diagnosing and recommending mitigations for turbomachinery faults found in the field, based on data, teardown, or other observation

- Documenting and communicating the rationale behind work in ways consistent with program direction, including part/assembly drawings, design reviews, test data reviews, and sundry analysis products

- Coordinating production of hardware, including with internal manufacturing team or external suppliers

- Applying sound engineering principles to all work, using methods and practices accepted in industry and/or based on valid physical principles

- Maintaining a respectful and professional work environment

- Mentoring less experienced staff for professional growth

Qualifications:

Strong candidates will have many of the following qualifications. It is not necessary to have all, and those with fewer qualifications are still encouraged to apply.

- Bachelor’s degree in Mechanical or Aerospace Engineering, or equivalent

- At least 15 years of experience

- Thorough understanding of fundamental principles of turbomachinery, at both the system and component level

- Thorough understanding of compressible and incompressible flow

- Deep experience with turbomachinery in relevant applications, such as gas turbine engines, liquid rockets, and/or industrial processes

- Demonstrated capability to design, build, test, and/or service turbomachinery, moving mechanical assemblies, and/or propulsion systems

- Demonstrated capability to perform analysis using software tools and hand calculations

- Knowledge of turbomachinery support systems and components, such as secondary flows, bearings, and seals

- Proficiency with computational fluid dynamics (CFD) software, such as ANSYS FLUENT

- Proficiency with 3D mechanical design CAD package(s)

- Proficiency with PLM software to manage and release designs and configurations

- Proficiency with industry best practices for part/assembly drawings, geometric dimensioning and tolerancing (GD&T), and hardware release

- Proficiency with finite element analysis (FEA) software, such as ANSYS Mechanical

- Experience in the aerospace industry, especially at a startup

- Experience with aerospace propulsion testing (gas turbines and/or rockets)

- This position may be subject to U.S. export control requirements, including those under the Export Administration Regulations (EAR). As a result, the successful candidate’s hire may be contingent upon the Company securing the appropriate export authorization for employment, and the candidate’s assistance in this process

Propulsion Responsible Engineer

ExpandJob Title: Propulsion Responsible Engineer

Description:

Velontra is seeking a propulsion responsible engineer. This engineer will oversee the development and field operation of one or more propulsion systems. This includes subsonic, supersonic, and/or hypersonic gas-turbine based systems, or critical subsystems thereof. The propulsion responsible engineer is a well-rounded propulsion generalist, with a variety of skill sets, who is able to see the big picture and drive the system to full maturity.

Responsibilities:

The propulsion responsible engineer is responsible for the following:

- Owning one or more propulsion systems over its full product life cycle

- Performing system-level sizing, design, and analysis of the product’s thermodynamic cycle at various levels of granularity

- Performing detailed design and analysis of key hardware systems

- Managing hardware assembly definitions and configuration control in product lifecycle management (PLM) and computer-aided design (CAD) software

- Planning and executing test programs to develop and/or field the product, including laying out test objectives, selecting instrumentation to gather key data, defining test approaches, and coordinating resources and schedules

- Interpreting test data to compare as-tested performance to design intent, identify issues, redirect testing, and modify designs as needed

- Documenting and communicating the rationale behind work in ways consistent with program direction, including part/assembly drawings, design reviews, test data reviews, test plans, and sundry analysis products

- Coordinating production of hardware, including with internal manufacturing team or external suppliers

- Maintaining project schedules and communicating with management to ensure work always stays on track and coordinated with company at large

- Applying sound engineering principles to all work, using methods and practices accepted in industry and/or based on valid physical principles

- Delegating and managing the foregoing, as needed, to other team members

- Maintaining a respectful and professional work environment

Qualifications:

Strong candidates will have many of the following qualifications. It is not necessary to have all, and those with fewer qualifications are still encouraged to apply.

- Bachelor’s degree in Mechanical or Aerospace Engineering, or equivalent

- Understanding of fundamental principles of aerospace propulsion devices

- Understanding of compressible and incompressible flow

- Capability to perform analysis using software tools and hand calculations

- Proficiency with at least one coding language commonly used in engineering, such as Matlab or Python

- Proficiency with 3D mechanical design CAD package(s)

- Proficiency with finite element analysis (FEA) software, such as ANSYS Mechanical

- Hands-on experience with aerospace or mechanical systems, in areas such as manufacturing, assembly, test, and/or flight operations

- This position may be subject to U.S. export control requirements, including those under the Export Administration Regulations (EAR). As a result, the successful candidate’s hire may be contingent upon the Company securing the appropriate export authorization for employment, and the candidate’s assistance in this process

Senior Turbomachinery Engineer

ExpandJob Title: Senior Turbomachinery Engineer

Description:

Velontra is seeking a senior turbomachinery engineer. This engineer will design, source, and test all types of turbomachinery hardware. This includes compressors, turbines, pumps, rotating assemblies, support structure, secondary flow systems, bearings, and seals.

Responsibilities:

The turbomachinery engineer is responsible for the following:

- Owning various turbomachinery hardware designs over the full product life cycle

- Performing system-level sizing of turbomachinery to fulfill vehicle requirements

- Performing detailed design and analysis of turbomachinery components based on system-level sizing and other requirements

- Developing static, dynamic, and/or thermal loads for use in design, based on test data and/or theory

- Managing hardware versions and configurations in product lifecycle management (PLM) and computer-aided design (CAD) software

- Specifying test approaches, including selecting instrumentation and providing test requirements, to validate designs

- Interpreting test data to compare as-tested performance to design intent

- Diagnosing and recommending mitigations for turbomachinery faults found in the field, based on data, teardown, or other observation

- Documenting and communicating the rationale behind work in ways consistent with program direction, including part/assembly drawings, design reviews, test data reviews, and sundry analysis products

- Coordinating production of hardware, including with internal manufacturing team or external suppliers

- Applying sound engineering principles to all work, using methods and practices accepted in industry and/or based on valid physical principles

- Maintaining a respectful and professional work environment

Qualifications:

Strong candidates will have many of the following qualifications. It is not necessary to have all, and those with fewer qualifications are still encouraged to apply.

- Bachelor’s degree in Mechanical or Aerospace Engineering, or equivalent

- At least 5 years of experience

- Understanding of fundamental principles of turbomachinery

- Understanding of compressible and incompressible flow

- Experience with turbomachinery in relevant applications, such as gas turbine engines, liquid rockets, and/or industrial processes

- Capability to design, build, test, and/or service turbomachinery, moving mechanical assemblies, and/or propulsion systems

- Capability to perform analysis using software tools and hand calculations

- Knowledge of turbomachinery support systems and components, such as secondary flows, bearings, and seals

- Proficiency with computational fluid dynamics (CFD) software, such as ANSYS FLUENT

- Proficiency with 3D mechanical design CAD package(s)

- Proficiency with PLM software to manage and release designs and configurations

- Proficiency with industry best practices for part/assembly drawings, geometric dimensioning and tolerancing (GD&T), and hardware release

- Proficiency with finite element analysis (FEA) software, such as ANSYS Mechanical

- Experience in the aerospace industry, especially at a startup

- Experience with aerospace propulsion testing (gas turbines and/or rockets)

- This position may be subject to U.S. export control requirements, including those under the Export Administration Regulations (EAR). As a result, the successful candidate’s hire may be contingent upon the Company securing the appropriate export authorization for employment, and the candidate’s assistance in this process

Turbomachinery Engineer

ExpandJob Title: Turbomachinery Engineer

Description:

Velontra is seeking a turbomachinery engineer. This engineer will design, source, and test all types of turbomachinery hardware. This includes compressors, turbines, pumps, rotating assemblies, support structure, secondary flow systems, bearings, and seals.

Responsibilities:

The turbomachinery engineer is responsible for the following:

- Owning various turbomachinery hardware designs over full product life cycle

- Performing system-level sizing of turbomachinery to fulfill vehicle requirements

- Performing detailed design and analysis of turbomachinery components based on system-level sizing and other requirements

- Developing static, dynamic, and/or thermal loads for use in design, based on test data and/or theory

- Managing hardware versions and configurations in product lifecycle management (PLM) and computer-aided design (CAD) software

- Specifying test approaches, including selecting instrumentation and providing test requirements, to validate designs

- Interpreting test data to compare as-tested performance to design intent

- Diagnosing and recommending mitigations for turbomachinery faults found in the field, based on data, teardown, or other observation

- Documenting and communicating the rationale behind work in ways consistent with program direction, including part/assembly drawings, design reviews, test data reviews, and sundry analysis products

- Coordinating production of hardware, including with internal manufacturing team or external suppliers

- Applying sound engineering principles to all work, using methods and practices accepted in industry and/or based on valid physical principles

- Maintaining a respectful and professional work environment

Qualifications:

Strong candidates will have many of the following qualifications. It is not necessary to have all, and those with fewer qualifications are still encouraged to apply.

- Bachelor’s degree in Mechanical or Aerospace Engineering, or equivalent

- Understanding of fundamental principles of turbomachinery

- Understanding of compressible and incompressible flow

- Capability to perform analysis using software tools and hand calculations

- Proficiency with computational fluid dynamics (CFD) software, such as ANSYS

FLUENT:

- Proficiency with 3D mechanical design CAD package(s)

- Proficiency with finite element analysis (FEA) software, such as ANSYS Mechanical

- This position may be subject to U.S. export control requirements, including those under the Export Administration Regulations (EAR). As a result, the successful candidate’s hire may be contingent upon the Company securing the appropriate export authorization for employment, and the candidate’s assistance in this process